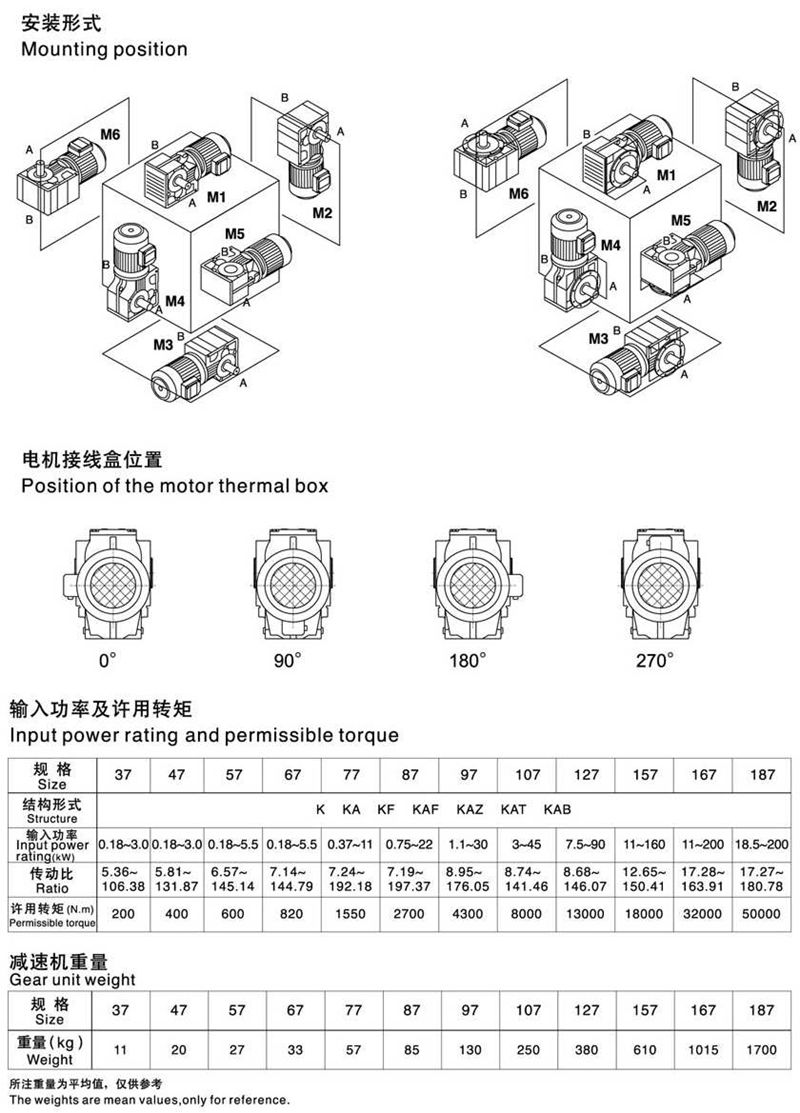

| Input Power | : | 0.18~200 kW |

| Max. Torque | : | Up to 50000 N.m |

| Input Speed | : | 3000, 1500, 1000, 750 r/min |

| Ratio | : | 8.04~13432.68 (i) |

| Gearsets | : | Hardened helical gears |

| Output Design | : | Shaft or flange |

| Mounting Methods | : | Foot, flange or shaft mounted |

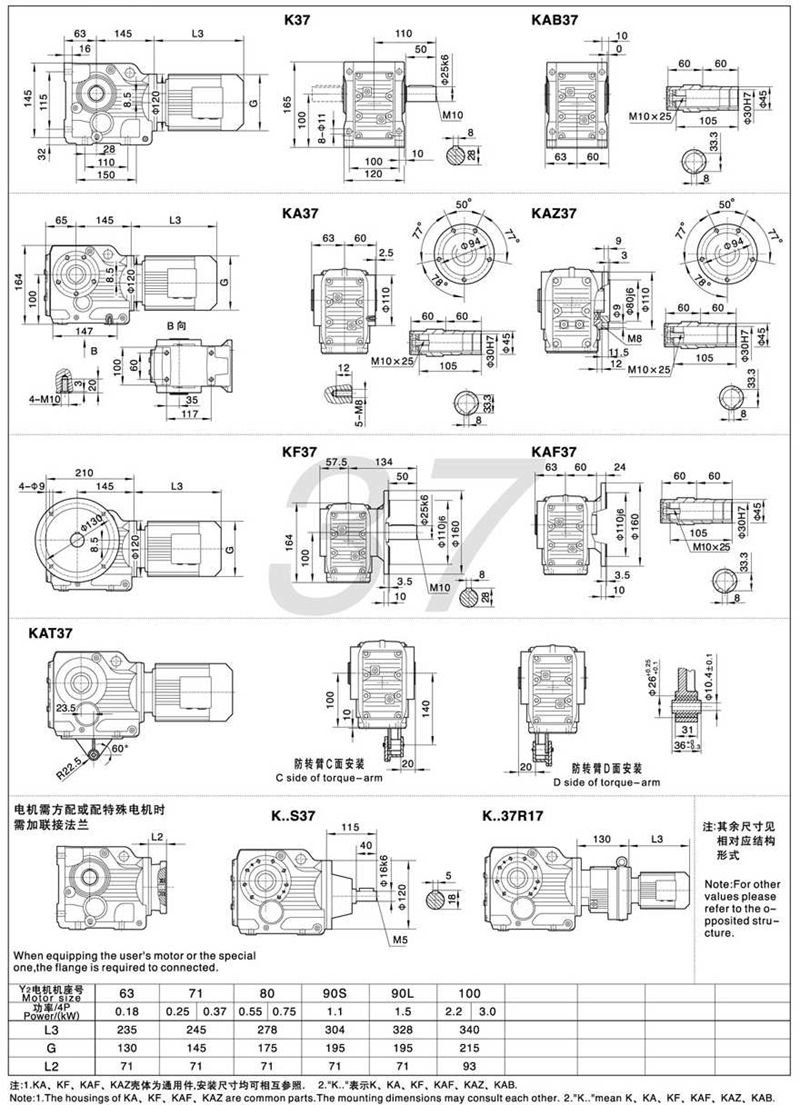

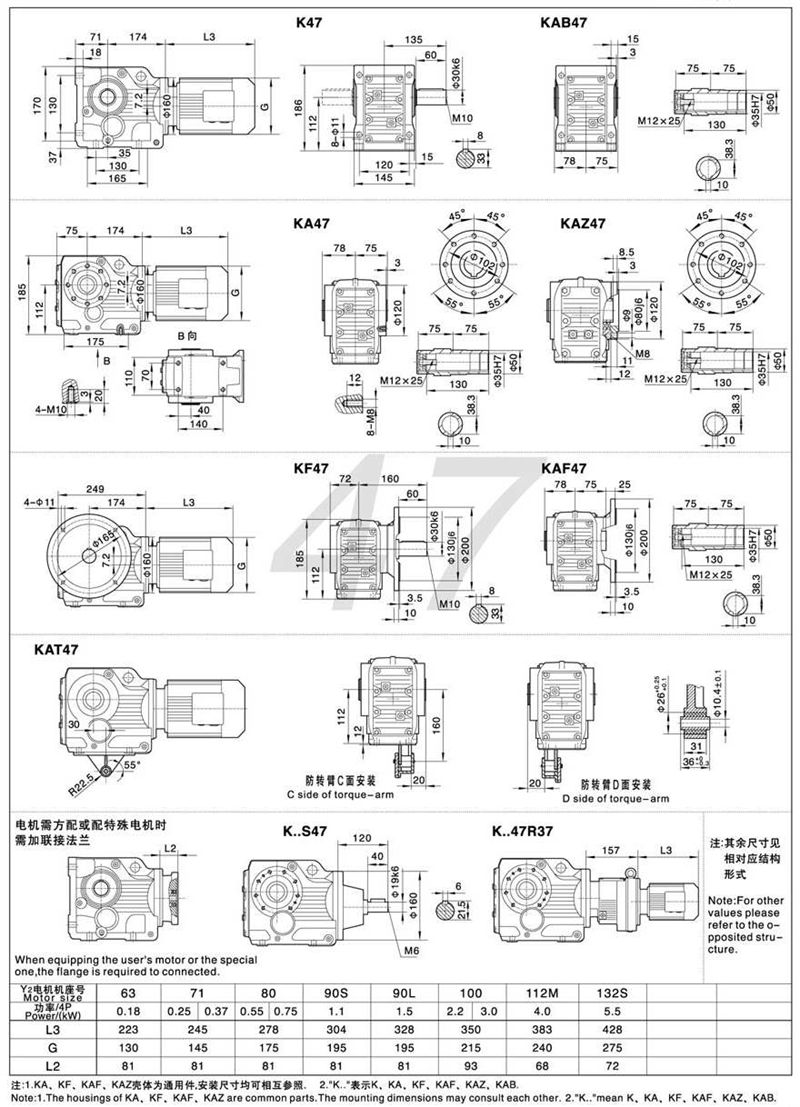

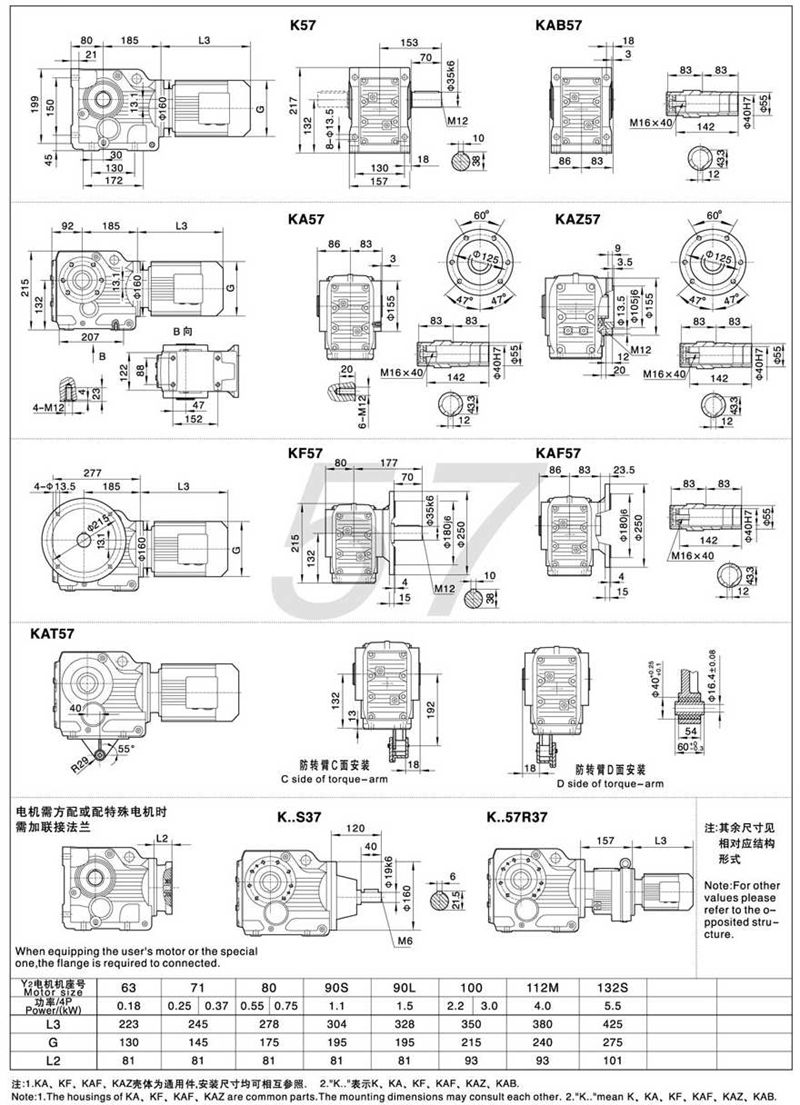

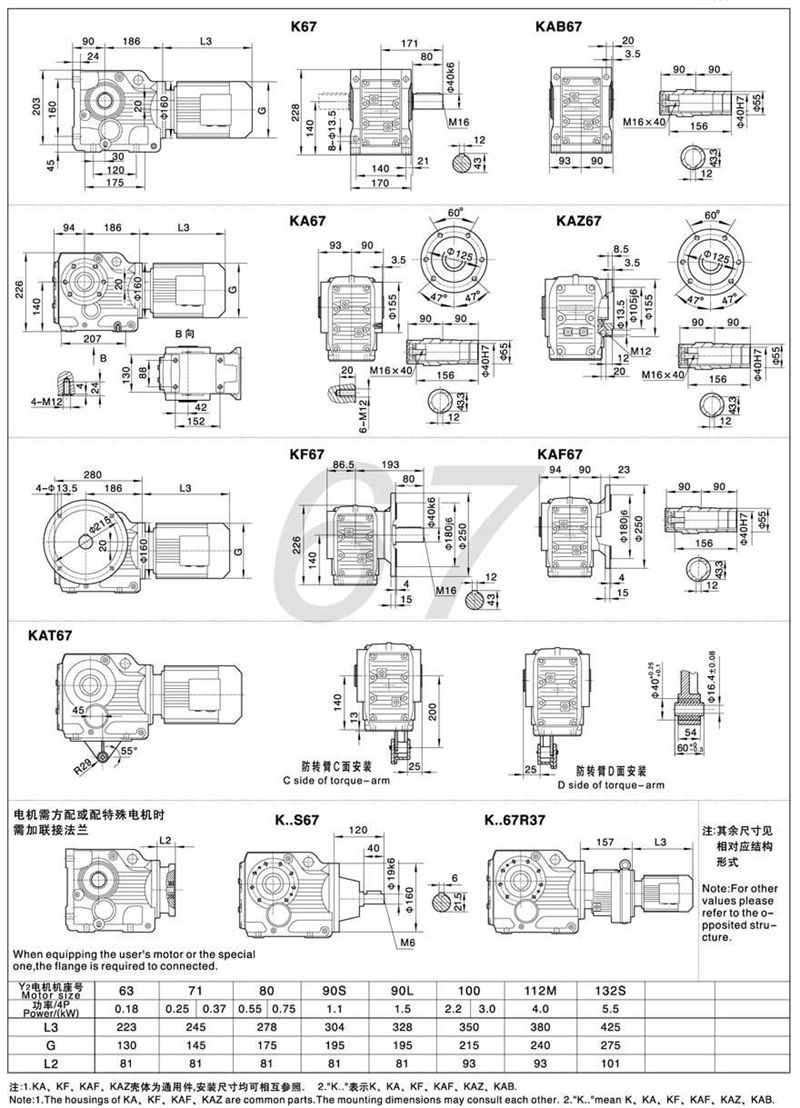

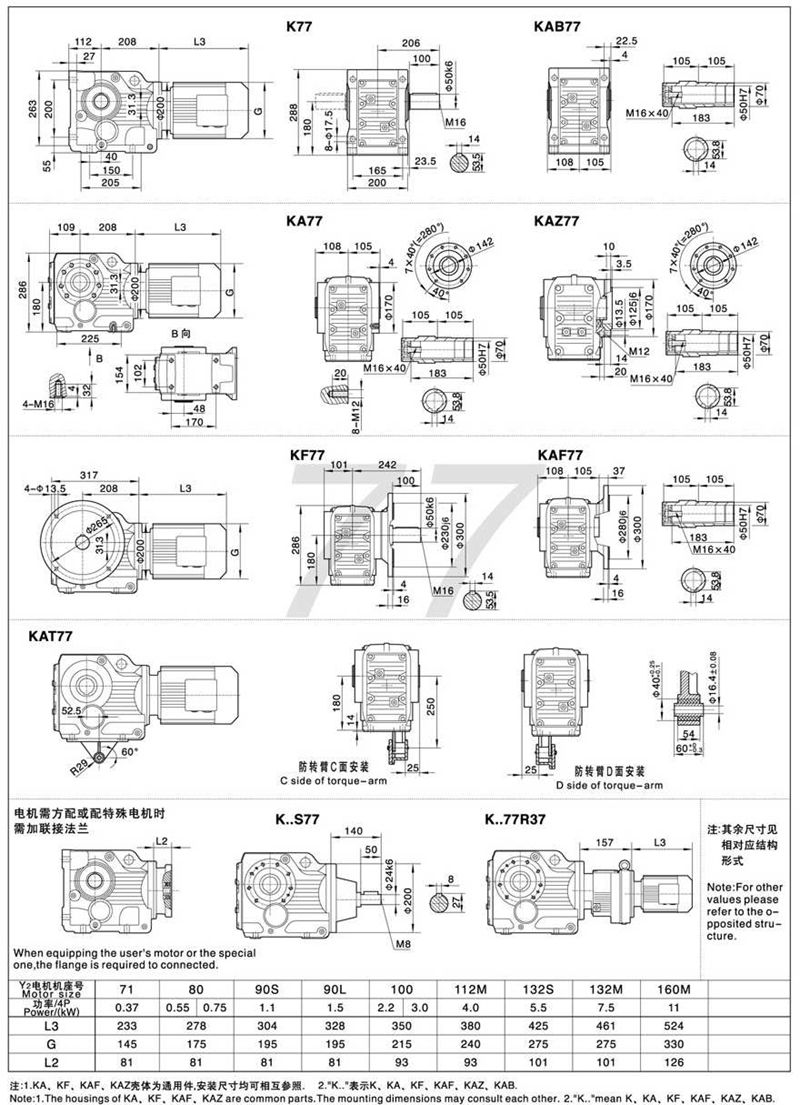

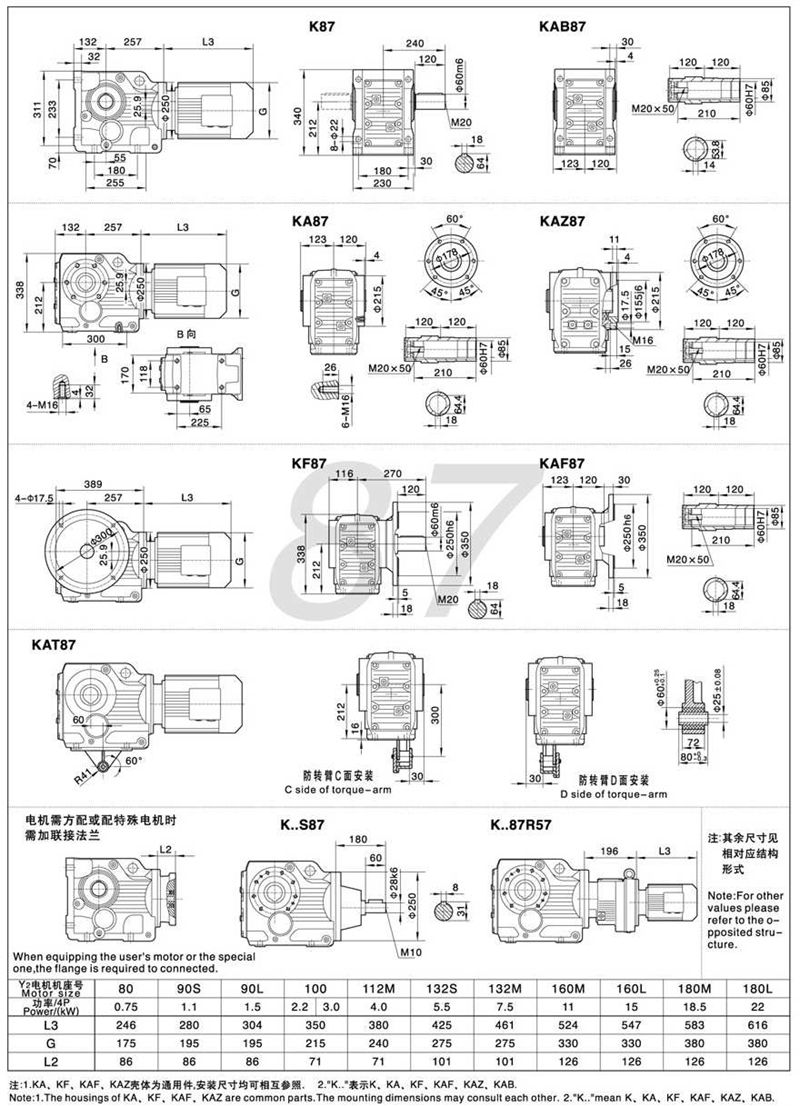

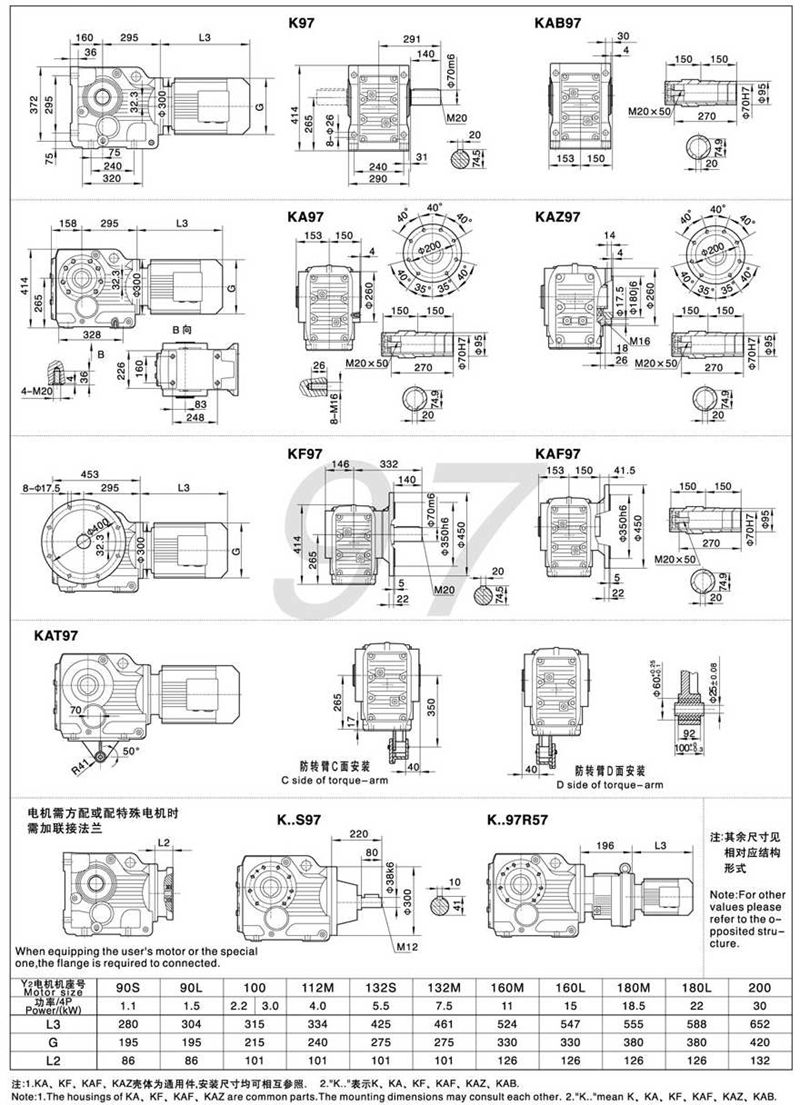

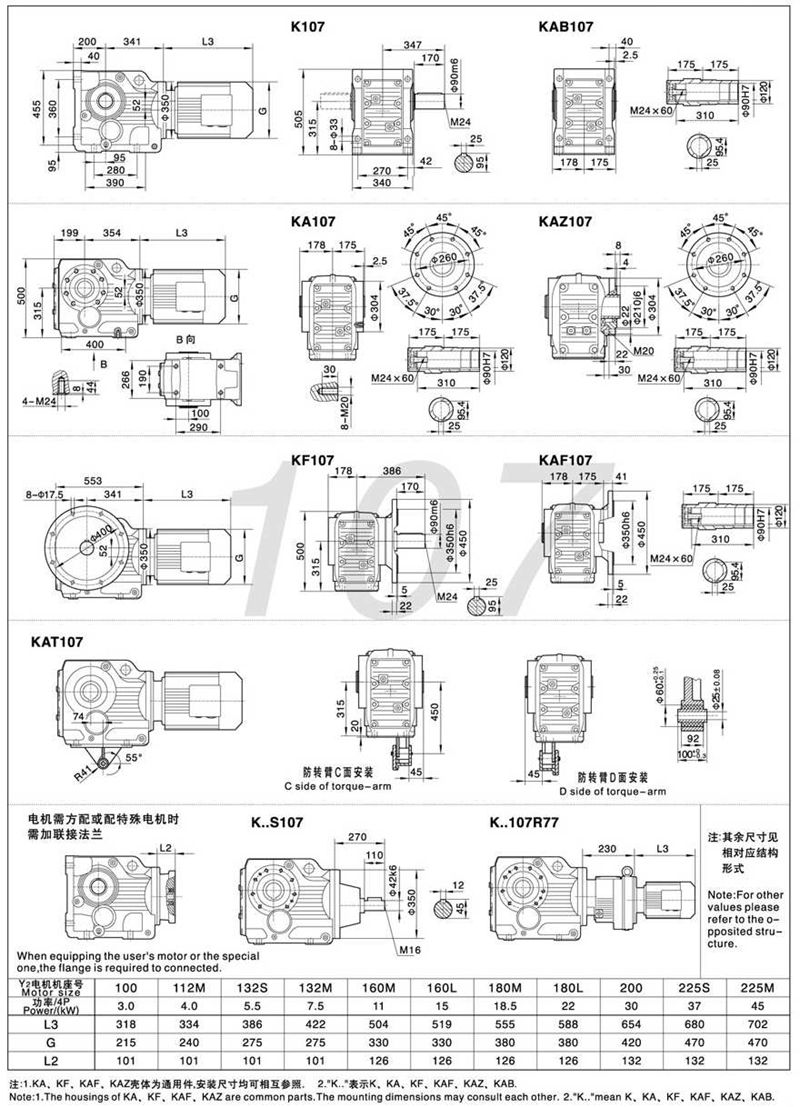

| Available Models | : | K, KA, KAB, KF, KAF, KAZ, KAT, KS, KH, KV, |

| Housing Material | : | High strength cast iron |

| Brand Bearing | : | C&U, NSK, SKF, FAG |

| Cooling Methods | : | Natural cooling |

K Series Helical Bevel Gear Motor

Rated Power: 0.18~200 kW

Rated Torque: Up to 50000 N.m

Rated Ratio: 8.04~13432.68

Gear Arrangement: Helical Bevel Gears

Shafts Position: Right Angle

Mounting Methods: Foot, Flange, Shaft Mounted

Housing: Cast Iron

Models

K Series – Foot-mounted, solid shaft output

KAB Series – Foot-mounted, hollow shaft output

KA Series – Keyed hollow shaft output

KF Series – B5 Flange-mounted, solid shaft output

KAF Series – B5 Flange-mounted, hollow shaft output

KAZ Series – B14 Flange-mounted, hollow shaft output

KAT Series – Hollow shaft output, torque arm

KH, KHB, KHF, KHZ Series – Hollow shaft output, shrink disk

KV, KVB, KVF, KVZ Series – Hollow shaft output, splined hollow shaft

K(KA, KF, KAF, KAB, KAZ)S Series – Solid shaft input

Input Design

Equipped with Electric Motors

Solid Shaft Input

IEC, GOST, NEMA Motor Flange

Output Design

Solid Shaft Output

Hollow Shaft Output

Available Drive Motors

General Motors of 1 Phase or 3 Phase AC

Brake Motors

Variable Frequency Variable Speed Motors

Variable-pole Multi-speed Motors

Explosion-proof Motors

Permanent Magnet Motors

DC Motors

Servo Motors

Brushless Motors

Other Motors

Available Mounting Methods

Foot Mounted

Flange Mounted

Shaft mounted

Features

Compact structure, modular design

High transmission efficiency up to 96%

Variable reduction ratio allowed

Variable driving power allowed

High performance, high safety factor, energy-saving, small vibration, low noise, high precision, big torque and long working life

Can be combined with other types of gear motors, such as R Series, PX Series, G Series, MB Series, UDL Series etc.

Service Conditions

Ambient Temperature: -40~50°C

Altitude: 1000 m.a.s.l

Working Duty: S1(Continuous)

Humidity: ≦90%

Cooling Method: Natural Cooling

Lubrication: Oil-bath and Splash Lubrication (The lubrication should be heated above 0°C, if temperature of machine is below 0°C when it start working)

Suitable for normal-reverse rotation

Application

Waste water treatment

Dredgers

Metal working mills

Conveyors

Cranes

Mixer

Crusher

Cooling towers

Paper machine

Cableways

Cement industry

Petroleum industry

Textile machinery

Food machine

Power machine

Construction machine

Metallurgy machine

Cement machine

Water conservancy machine

Chemical machine

Mining machine

Transportation machine

Rubber machine

Petroleum machine

Other machines and industries

|

Model |

Output Shaft Dia. (mm) |

Power |

Ratio |

Max. Torque |

|

|

Solid Shaft |

Hollow Shaft |

(kW) |

(i) |

(Nm) |

|

|

K37 |

25mm |

30mm |

0.18~3.0 |

5.36~106.38 |

200 |

|

K47 |

30mm |

35mm |

0.18~3.0 |

5.81~131.87 |

400 |

|

K57 |

35mm |

40mm |

0.18~5.5 |

6.57~145.15 |

600 |

|

K67 |

40mm |

40mm |

0.18~5.5 |

7.14~144.79 |

820 |

|

K77 |

50mm |

50mm |

0.37~11 |

7.22~192.18 |

1550 |

|

K87 |

60mm |

60mm |

0.75~22 |

7.19~197.27 |

2700 |

|

K97 |

70mm |

70mm |

1.3~30 |

8.95~175.47 |

4300 |

|

K107 |

90mm |

90mm |

3~45 |

8.74~141.93 |

8000 |

|

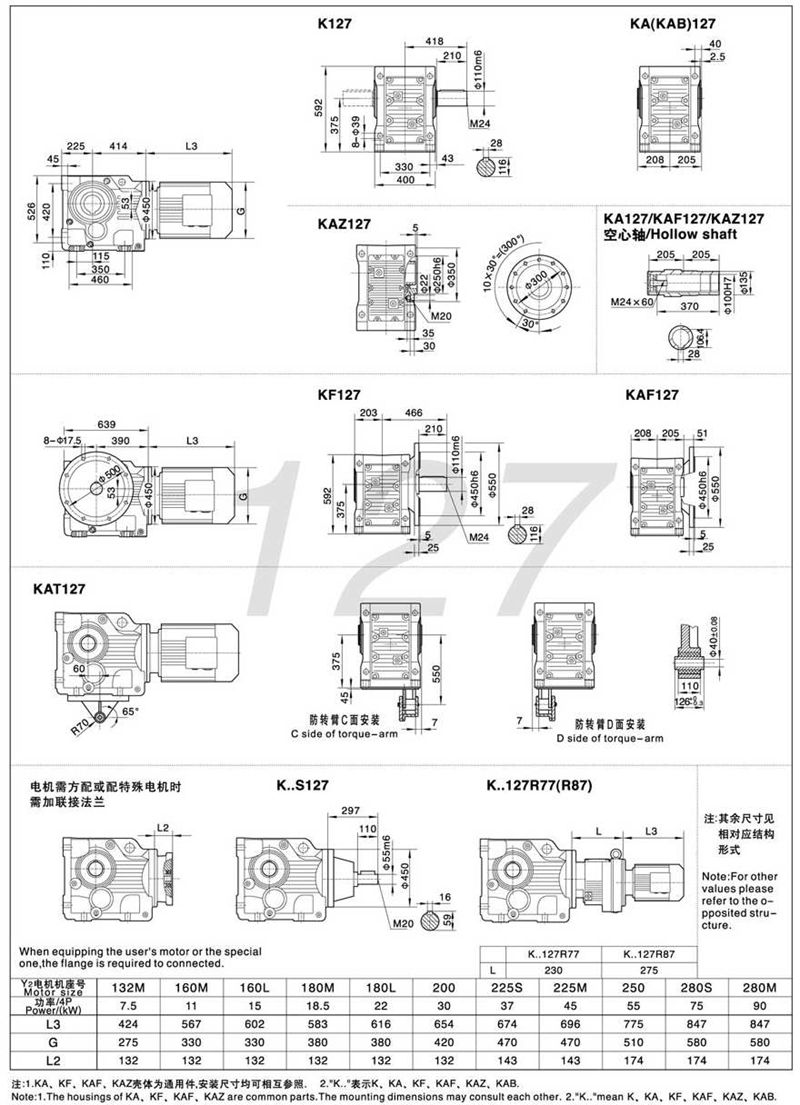

K127 |

110mm |

100mm |

7.5~90 |

8.68~146.07 |

13000 |

|

K157 |

120mm |

120mm |

11~160 |

12.66~150.03 |

18000 |

|

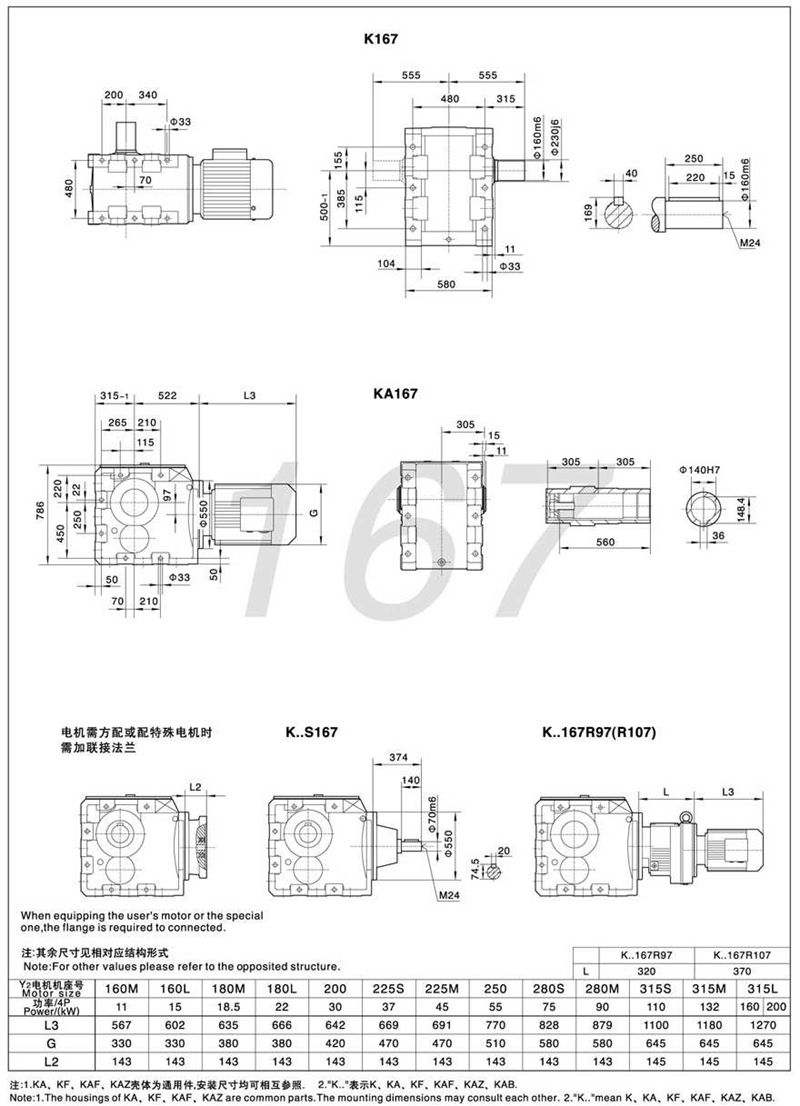

K167 |

160mm |

140mm |

11~200 |

17.35~164.44 |

32000 |

|

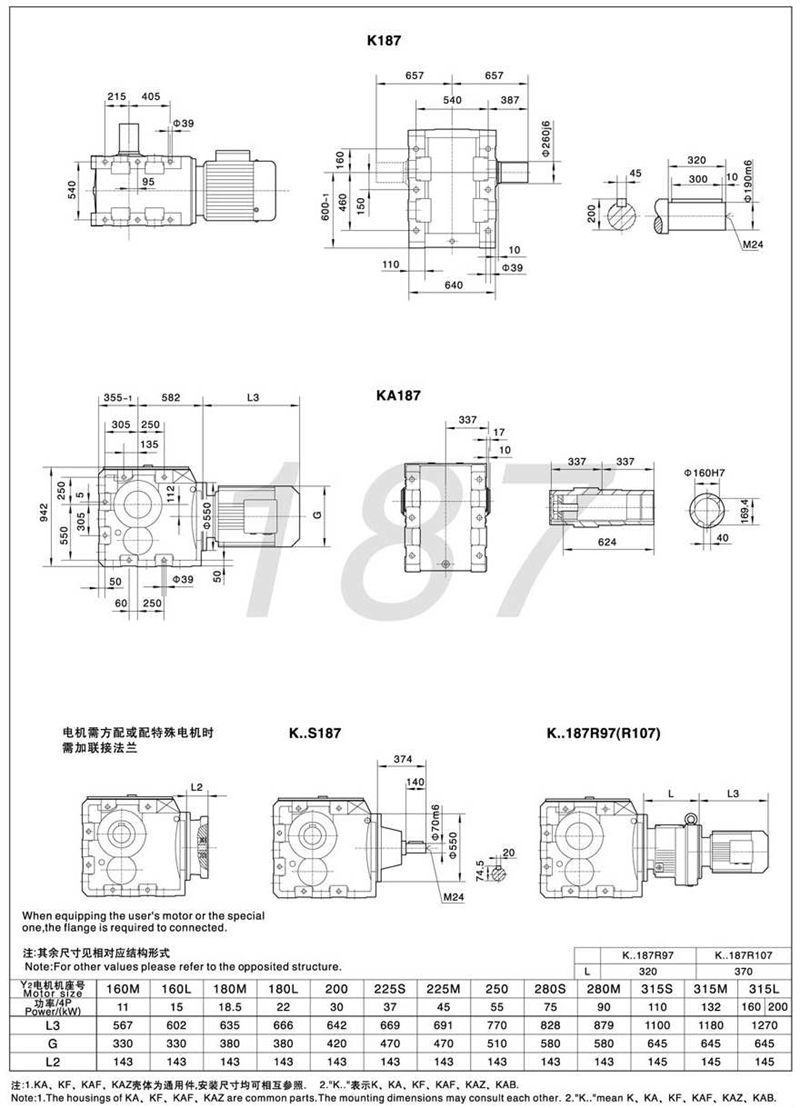

K187 |

190mm |

160mm |

18.5~200 |

17.97~178.37 |

50000 |

Notes:

Customized input & output shaft and hole size allowed.

Thanks for your supporting. We will back to you with solution after you leave your requirements and contacts.