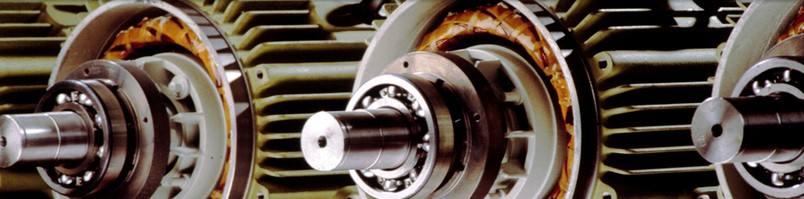

The rotor part of three phase induction motor usually needs to be supported by two sets of bearings before and after, and the rotor is positioned in radial and axial direction relative to the stator. According to different use requirements, such as: load, required rotation accuracy, and manufacturing costs and other requirements, the bearing configuration of three-phase induction motor is generally adopted: one end is fixed, one end is floating configuration; A pre-adjusted configuration fixed at both ends; For example, floating configuration on both ends.

一、One end is fixed and the other end is floating

The fixed-end bearing is fixed at the same time through the shaft and the end cover bearing chamber, and the radial support is carried out at one end of the shaft, and the axial positioning function is played in the two axial directions at the same time. Bearings at the fixed end must be radial bearings that can bear the combined radial and axial loads. Deep groove ball bearings are most commonly used in three-phase induction motor products. In some other equipment and machinery, double-row or paired single-row angular contact ball bearings and other bearings that can bear the combined loads are also used.

For the motor with three-bearing structure, the bearing combination is used for positioning, that is, the radial bearing that can only bear pure radial load (cylindrical roller bearing with ring without flange) and the combination of deep groove ball bearing that can bear the combined load. In this configuration, the other bearing deep groove ball bearing is only used for axial positioning in two directions, and a certain radial degree of freedom must be left in the bearing chamber, that is, the diameter direction of the bearing chamber is clearance fit.

The floating end bearing of the three-phase induction motor is at the other end of the shaft, only doing radial support, so the floating end bearing can be deep groove ball bearing, can also be column bearing, for the large load of three-phase asynchronous motor, and impact load motor in most cases using cylindrical roller bearings. In this configuration, the shaft must be allowed to have a certain axial displacement, so that there will be no mutual force between bearings. During the operation of the motor, when the shaft expands due to heat, the axial displacement can be achieved inside some types of bearings (cylindrical roller bearings). Axial displacement can also occur between one of the bearing rings and its connected components, preferably between the bearing outer ring and the bearing chamber. In view of this, the choice of N type or NU type bearing needs the designer to carry out comparative analysis and demonstration.

There are many different combinations of fixed-end and floating end bearing configurations, and the following are some of the more common combinations. For rigid bearing configuration, the combination that the axial displacement can be achieved in the bearing should be used, such as the combination of deep groove ball bearing and cylindrical roller bearing; Combination of double row angular contact ball bearing and cylindrical roller bearing; Paired single row tapered roller bearing and cylindrical roller bearing combination, of course, there are some other combination methods, for this design, it is recommended to carry out joint analysis and selection with bearing manufacturers.

In the above combination, the Angle error between the shaft and the bearing seat must be reduced to a minimum. If the application situation does not allow, it is recommended to use a combination of self-aligning bearings that can withstand a larger Angle error. These configurations can withstand a certain Angle error and axial displacement, and can avoid internal axial forces in the shafting.

For the bearing configuration of the inner ring bearing rotating load, the shaft length change needs to be adjusted between the bearing and its matching surface, the axial displacement should be between the outer ring and the bearing chamber, the most commonly used combination is deep groove ball bearing and deep groove ball bearing; Pair single row angular contact ball bearing and deep groove ball bearing combination.

二、Floating bearing configuration

The floating bearing configuration is also a cross-positioning method, which is suitable for applications where only moderate axial positioning is required, or other components on the shaft are used for axial positioning. In this configuration, the most important thing is that each bearing can be axially displaced. It can be between one of the bearing rings and its mating surface, but it is best between the bearing outer ring and the bearing chamber.

三、Pre-adjusted bearing configuration

In the pre-adjusted bearing configuration, the shaft is positioned axially by a bearing in a certain direction, and the other direction is fixed by another bearing. This configuration is called "crossover" positioning and is usually used for shorter shafting lengths. All radial bearings capable of bearing axial loads (in one or both directions) are suitable for this configuration. In some cases, single-row angular contact ball bearings or tapered roller bearings are used in cross-positioning configurations, but some pretightening may be required.