With the continuous improvement of equipment intelligence level and high reliability requirements, the drive electric motor online status monitoring, real-time feedback of position and speed signal tends to be standard, encoder, over speed switch, PT00, PTC, vibration sensor and other three-phase induction motor additional devices are more and more popular. Understanding these add-ons and achieving organic integration with three phase induction motors is crucial for electric motor manufacturers. From The Chinese electric motor manufacturer - Langrui electric motor factory, let us talk about the vibration sensors that are very common on the telephone in recent years.

Working principle of vibration sensor

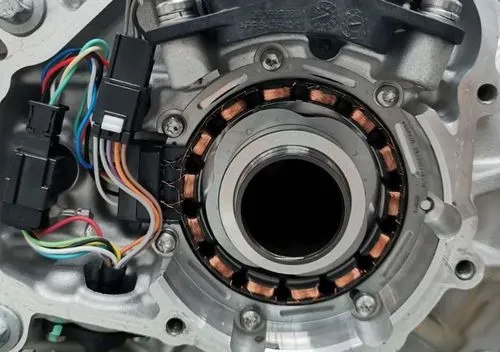

Vibration sensor is one of the key components in the condition monitoring of three-phase electric motor. Its function is to convert mechanical vibration into proportional electric quantity. Because it is actually a mechanical and electrical energy conversion device, it is called transducer, vibration pickup and so on.

The vibration sensor does not directly transform the original mechanical quantity into electric quantity, but takes the original mechanical quantity as the input of the vibration sensor, and then receives it by the mechanical receiving part, forming another mechanical quantity suitable for transformation, and finally transforms into electric quantity by the mechanical and electrical transformation part. Therefore, the working performance of the sensor is determined by mechanical reception and electromechanical transformation.

Vibration sensor classification

According to the measurement method and physical properties of the measurement process, vibration sensors can be divided into mechanical, optical and electrical measurement types.

¡ñ Mechanical: the engineering vibration parameters into mechanical signals, the mechanical system after amplification, measurement, record. Commonly used instruments are lever type vibration measuring instrument and Geiger vibration measuring instrument, can measure the frequency is low, the accuracy is poor, but in the field test is relatively simple and convenient.

¡ñ Optical type: the engineering vibration parameters are converted into optical signals, which are displayed and recorded after amplification by the optical system.

¡ñ Electric measurement: the engineering vibration parameters into electrical signals, the electronic circuit after amplification display and record.

Application of vibration sensor

Vibration sensor in electric motor manufacturing and testing links is the most widely used motor vibration tester, almost every motor manufacturer will use.

In the process of precision industrial production, electric motor vibration parameters reflect the imbalance of machinery and equipment, electrical defects, fastener looseness and other abnormal phenomena, which lead to the vibration problem of precision decline and bring safety risks.

For large equipment with three phase electric motors, customers often equipped with vibration sensors. Generally, sensors and controllers are used together. Through parameter setting, motor power will be forcibly cut off in abnormal state, which will protect the motor and equipment.