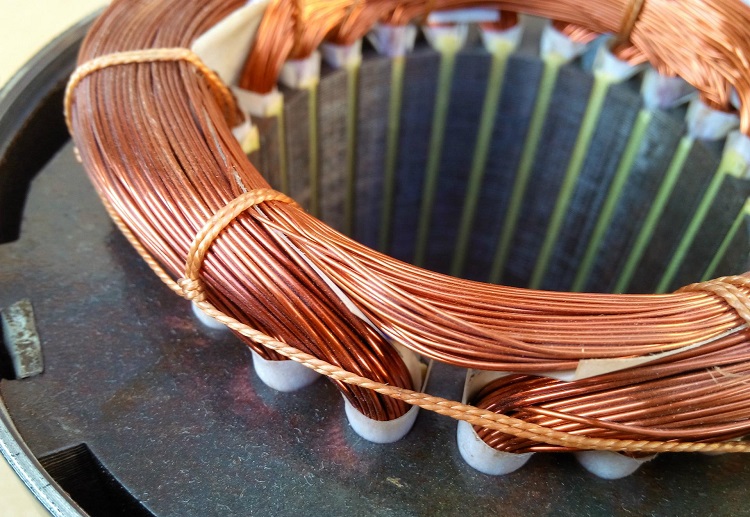

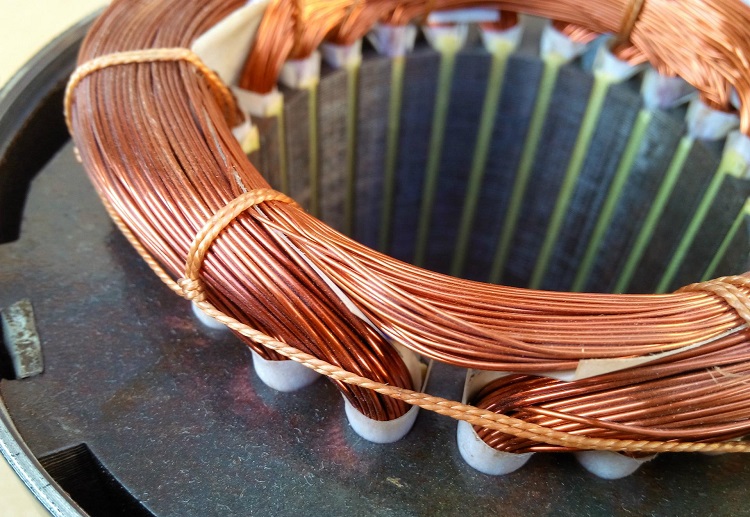

Look at the

3 phase induction motor motor nameplate and instructions Aluminum core motor will have one more "L" or "A" letter than the copper core motor model, and the same level of aluminum core motor is lighter than the copper core, and the volume will be larger. If it is a cottage, you may not know the surface, you can open the core of the motor color is different, pay attention to copper clad aluminum, so cut off the line of view, if the inside is white aluminum. If it can be dismantled, scrape the lines away where they don't care, and stick them with high-temperature adhesive tape after reading. If it cannot be disassembled, compare the coil resistance. The aluminum core has a larger resistance than the copper core.

Electric motor manufacturers believe that the advantages of copper core motors are as follows:

1. The conductive properties of copper are better than that of aluminum. The current carrying capacity of copper is 6 ampere per square and the aluminum wire is 5 ampere. Therefore, the aluminum wire motor is prone to heat for a long time. Of course, the general case temperature is kept within 90 degrees. The overall performance is not as good as that of a copper wire motor. The power of the aluminum core motor is much smaller than that of the copper core, and it is easy to generate heat because the current carrying capacity is small. General aluminum wire is about 20 percent smaller than copper wire.

2, Pure copper wire 3 phase induction motor is of course more durable. Aluminum is slightly larger than the copper resistance, and the heat is higher during use. It is very easy to burn out the motor. Moreover, aluminum and copper welding cannot be naturally combined, and the power line connection point is also prone to burnout. Therefore, the life of the general aluminum wire motor water pump is far lower than that of the pure copper wire motor water pump.

3, Pure copper wire 3 phase induction motor more power. The resistance of the circuit element is proportional to the size of the heat. Larger resistance will result in greater heat.

4, Pure copper core motor noise is smaller. When noise increases by an average of 3 dB, noise energy doubles. Aluminum wire motor noise is about 7 dB higher than copper wire motor, so the noise of aluminum wire motor is more than double that of copper wire motor noise. Pure copper wire three-phase induction motor pump noise tested to only 58 decibels.

5, Pure copper wire three phase induction motor is relatively more durable. Because aluminum is larger than the copper resistor, the heat is higher during use, and it is easy to burn out the motor.

6, Aluminum wire quality will be lighter, relatively cheaper, but the mechanical strength is called poor, aluminum wire and then connected to the end of the line is easy to oxidize, after the oxidation of the line terminal will cause the temperature to rise, causing poor contact, is caused Failure of power failure or disconnection of multiple points, in addition to aluminum wire is not easy to weld, low strength and low melting point, it is easy to oxidize, resulting in high temperature and high loss.