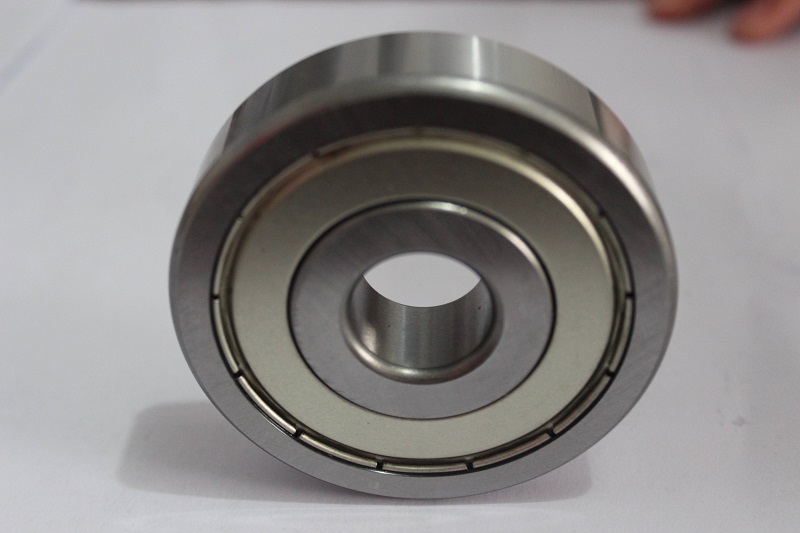

1, three phase induction motor running noise, you can try to add lubricant in the bearing some chemical additives, can reduce the bearing noise, a noise reduction additive with a low noise grease, bearing noise can be changed from the original Based on the lower 3.9 ~ 9.2dB, suitable for use in miniature or small bearings.

3, in the three phase induction motor bearings and seat hole by adding a middle sleeve, the damping system can be transmitted to the vibration transmitted to the bearing, but this requires deployment is appropriate, otherwise there may be the opposite effect. A further example is the use of acoustically sound-absorbing enclosures to noise-dampened bearing systems completely enclosed or as close as possible. The interior of the noise reduction cover is made of glass fiber or polyurethane foam, and the inner surface is a steel plate with a thickness of 0.6 to 1 mm. The surface of the noise reduction cover is uniformly distributed with small through holes of ¦Õ1.2 to 1.5 mm, and the total area of the small holes is about the whole Surface of 25% to 30%, the outer surface of the thickness of 2mm steel. Here, fiberglass or foam is used to eliminate higher frequency noise. Inner surfaces with small holes are used to eliminate lower frequency noise while thick steel outer plates are used to isolate noise.